Supply Cheap Aluminum Steel Coil Coating Line in China Maker

The aluminum industry has long been an essential part of global manufacturing, providing materials that are both lightweight and durable for a variety of applications. Over time, aluminum has become increasingly important due to its recyclability and its ability to contribute to more sustainable manufacturing practices. One of the key components in aluminum processing is the Aluminum Coil Coating Line, which plays a critical role in enhancing the functionality and sustainability of aluminum products.

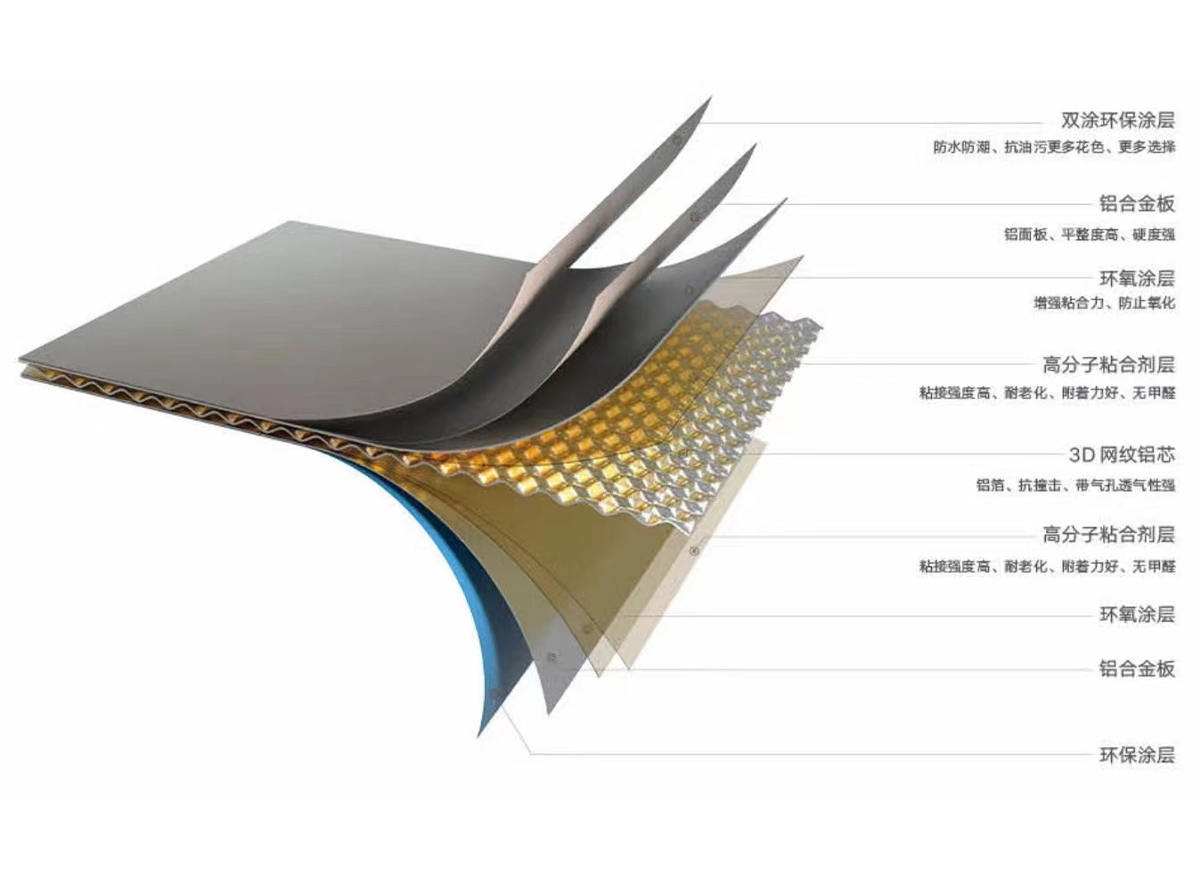

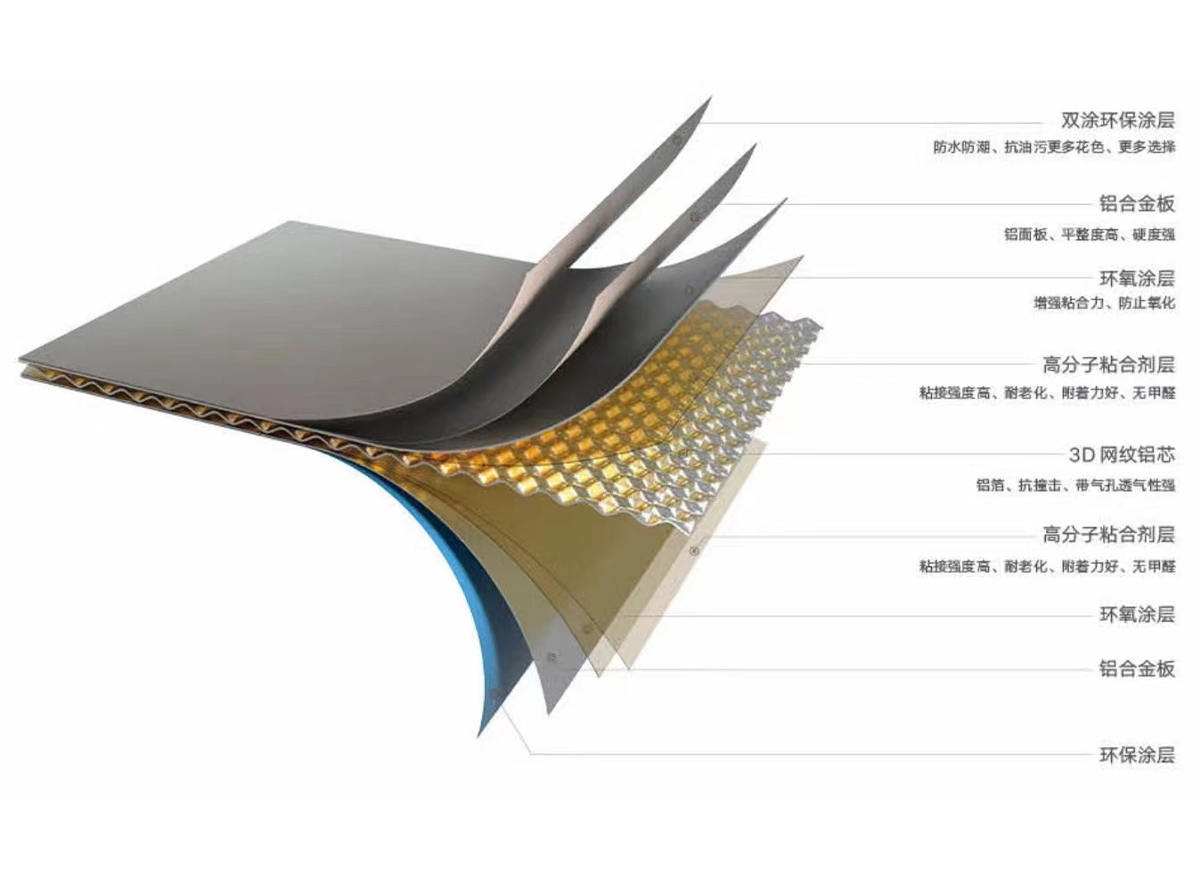

An Aluminum Coil Coating Line is a system designed to apply coatings to aluminum coils, which are then used in products such as roofing, siding, and automotive parts. This process involves several stages, including surface preparation, coating application, curing, and inspection. The precise control over each step ensures that the coatings are applied evenly and effectively, which is essential for achieving both aesthetic and functional qualities.

One of the significant benefits of an Aluminum Coil Coating Line is its ability to extend the lifespan of aluminum products. The coatings applied in the line act as a protective barrier against environmental elements such as moisture, UV rays, and chemicals. This increased durability reduces the need for frequent replacements, contributing to long-term resource efficiency. Moreover, the Aluminum Coil Coating Line can accommodate various coating types, including polyesters, PVDF, and epoxy-based coatings, offering tailored solutions for different industrial needs.

The sustainability aspect of the aluminum coil coating line is also evident in its ability to reduce waste and energy consumption. Modern coating lines are designed with precision and efficiency in mind, ensuring that small coating material is not wasted during the application process. Additionally, many Aluminum Coil Coating Lines are equipped with recycling systems that capture excess paint and solvents, reducing environmental impact. By reducing material waste and optimizing energy use, the Aluminum Coil Coating Line supports the broader goals of sustainability within the aluminum industry.

Another critical role of the Aluminum Coil Coating Line in sustainable practices is its ability to enhance the recyclability of aluminum products. Aluminum itself is all recyclable, and the coatings applied in the Aluminum Coil Coating Line do not hinder the recycling process. In fact, many of the coatings used today are designed to be compatible with recycling procedures, ensuring that the coated aluminum remains a valuable material at the end of its life cycle. This closed-loop recycling process is crucial for reducing the demand for raw materials and less environmental impact.

The Aluminum Coil Coating Line also contributes to sustainability through its adaptability to different production needs. With advancements in technology, these lines can be easily adjusted to handle varying production volumes and coating types. This flexibility allows manufacturers to meet demand efficiently while maintaining sustainable practices. The use of automated controls in modern Aluminum Coil Coating Lines ensures consistent quality and reduces the likelihood of defects, further less waste and increase resource use.

Furthermore, the coating process itself can be tailored to meet specific environmental standards. Water-based coatings, for instance, offer an eco-friendly alternative to solvent-based ones, significantly reducing harmful emissions. The Aluminum Coil Coating Line is also capable of applying coatings that reduce the need for additional treatments, such as anodizing, which can be energy-intensive and produce hazardous waste.

In addition to the direct environmental benefits, the use of an Aluminum Coil Coating Line supports the overall green building movement. Many industries, particularly construction, are increasingly focused on reducing their carbon footprint. Aluminum products coated using a high-performance Aluminum Coil Coating Line can help meet sustainability standards such as LEED certification. These coated products contribute to energy-efficient buildings by providing durable, long-lasting materials that require less maintenance and replacement over time.

The role of the Aluminum Coil Coating Line in sustainable metal processing practices cannot be overstated. It not only enhances the durability and functionality of aluminum products but also supports the industry's efforts to lessen environmental impact. By optimizing material usage, reducing waste, and promoting recyclability, the Aluminum Coil Coating Line is a key component of the aluminum industry's move toward greater sustainability. As demand for more sustainable manufacturing practices continues to grow, the Aluminum Coil Coating Line will remain a vital technology in the ongoing transformation of the metal processing sector.

In conclusion, the Aluminum Coil Coating Line is not just a vital tool for enhancing the properties of aluminum products; it is also an essential part of the industry's efforts to create more sustainable manufacturing practices. By improving product longevity, reducing waste, and facilitating recycling, the Aluminum Coil Coating Line plays a pivotal role in ensuring that the aluminum industry continues to contribute positively to a more sustainable future.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى