China ACP Production Line Aluminum Laminate Panel Manufacturing Wholesaler

The ACP production line plays a crucial role in modern manufacturing, particularly in the production of aluminum composite panels, which are widely used in construction, signage, and interior design. With the ever-increasing demand for high-quality and cost-effective products, manufacturers must carefully examine the factors that influence the efficiency of the ACP production line. By focusing on key elements such as automation, material selection, and process optimization, companies can reduce costs and enhance product quality while maintaining competitive advantages.

One of the more significant contributors to cost reduction in an ACP production line is automation. The introduction of advanced automated machinery has dramatically improved the speed and accuracy of manufacturing processes. Automated systems handle critical tasks such as cutting, bonding, and panel formation, reducing the risk of human error and speeding up production. This not only lowers labor costs but also ensures a higher level of consistency across products, resulting in improved quality control. Moreover, automation in the ACP production line helps to reduce material waste, which is essential for reducing overall production costs.

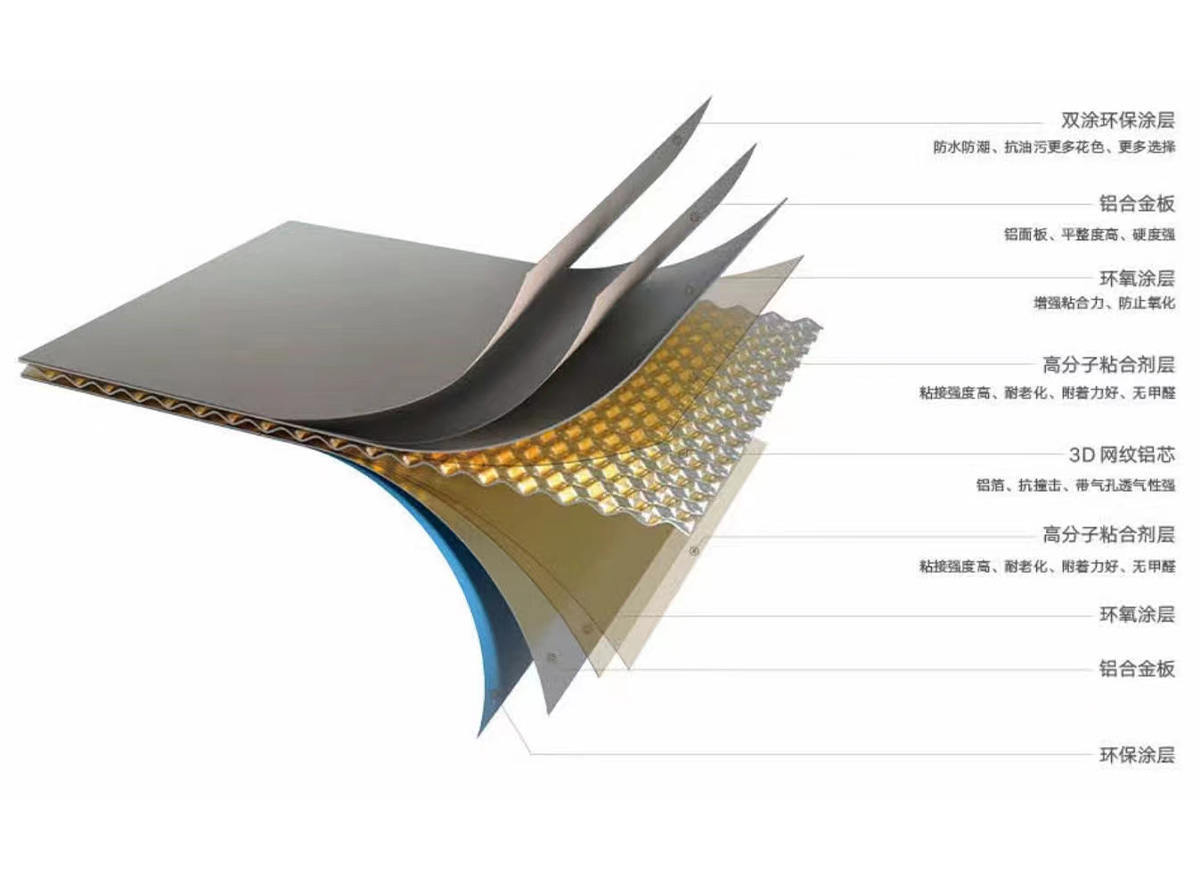

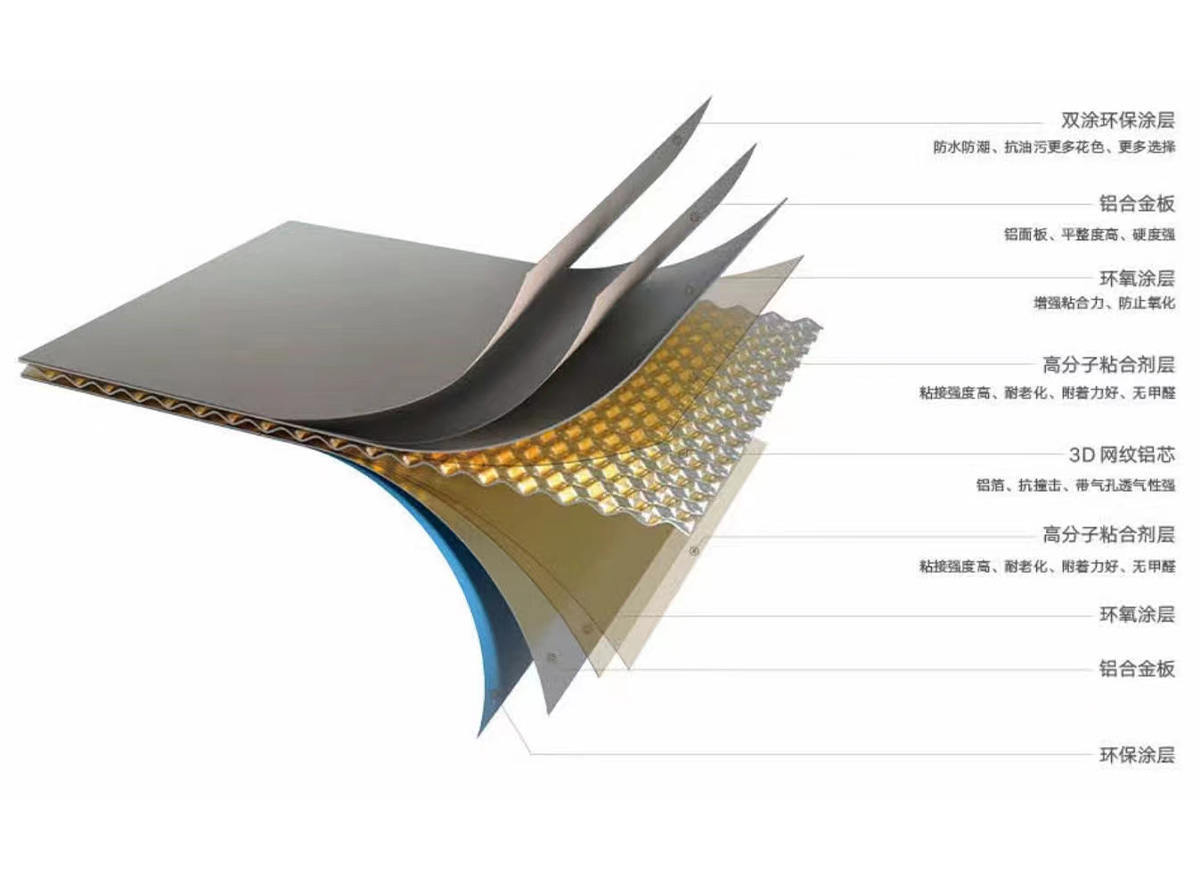

Material selection is another vital factor influencing both cost and product quality in the ACP production line. The raw materials used in the production of aluminum composite panels, such as aluminum coils and polyethylene cores, can significantly affect the final product's durability, appearance, and cost. By selecting high-quality yet affordable materials, manufacturers can strike the right balance between performance and cost. For instance, using premium aluminum alloys may enhance the panel’s resistance to corrosion and increase its longevity, which in turn adds value to the product. However, careful attention must be paid to cost-effective sourcing to avoid escalating production expenses.

Furthermore, the layout and design of the ACP production line itself can impact both cost efficiency and product quality. An optimized layout reduces unnecessary movement of materials and workers, improving workflow and decreasing operational costs. By strategically placing machines, conveyors, and storage areas, manufacturers can streamline their production processes, reducing downtime and delays. A well-organized ACP production line also promotes a safer working environment, which contributes to fewer workplace accidents and greater overall productivity.

The quality of the finished aluminum composite panels is also directly linked to the precision and calibration of the machinery used in the ACP production line. Regular maintenance and calibration of equipment help maintain the required standards of precision, ensuring the panels meet the expected specifications. Over time, neglected or poorly maintained machines can advance to defects such as warped panels, incorrect bonding, or inconsistent thickness, all of which compromise product quality. Investing in high-precision machinery and committing to regular maintenance is essential for sustaining product excellence in an ACP production line.

In addition to these factors, the implementation of quality control systems throughout the ACP production line is crucial. Inspecting the panels at various stages of production, such as during cutting, bonding, and finishing, allows manufacturers to catch defects early on, preventing the costly consequences of producing defective products. Statistical process control (SPC) tools can be employed to monitor key variables, ensuring that all panels meet rigorous quality standards. Consistent quality control in the ACP production line enhances the brand reputation and customer satisfaction, pilot to greater demand and increased profitability.

Environmental considerations also play an important role in the cost and quality dynamics of the ACP production line. As sustainability becomes more important in manufacturing, companies are adopting eco-friendly practices, such as recycling materials, reducing energy consumption, and less waste. These initiatives not only contribute to cost savings but also align with global environmental standards, which can be a selling point for customers who prioritize sustainability.

Training and skill development of the workforce involved in the ACP production line should not be overlooked. Skilled workers are essential for operating and troubleshooting sophisticated machinery, as well as ensuring that quality standards are consistently met. Ongoing training programs help employees stay updated on the latest industry practices and technological advancements, which can advance to improved operational efficiency and product quality.

In conclusion, the ACP production line is a complex system where several factors intersect to influence both cost reduction and product quality. Automation, material selection, layout optimization, equipment maintenance, quality control, environmental responsibility, and workforce training are all integral components that work together to enhance production efficiency and ensure high-quality aluminum composite panels. By focusing on these key factors, manufacturers can not only reduce their operational costs but also produce products that meet the growing demands of the market, maintaining a competitive edge in the industry.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى